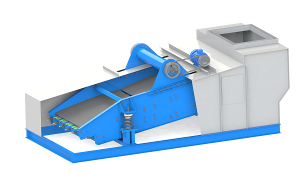

Asphalt plant DS-185-80

Артикул: ДС-185-80

«UfaDorMash» Production Association produces asphalt plants (AP) DS-185-80 (capacity-80 t/h). DS-185-80 model asphalt plant is certified as DS-185-80 for sale in the countries of CIS.

Advantages of own-produced asphalt concrete plants:

- DS-185-80 is a modular block design. Dimensions of modular blocks allow to carry asphalt concrete plant both by standard road trailers and rail containers.

- Engineering principle of DS-185-80 asphalt concrete plant is all the mounting and installation dimensions conformity to those of units and assemblies of DS-158, DS-185. Any unit can be replaced by appropriate replacement part purchased from dealers of «Kredmsh» Production Joint Stock Company.

- Our plants are completely manufactured of domestic metal in the Russian Federation. All the constituent parts, electric motors, gear units, pneumatics and electric components are delivered by Russian and European suppliers.

- All major components: mixer, smoke exhauster, sieve, weighing system, burner are designed according to the principle of double margin of safety. We effectively learned how to compensate for instability of humidity/dustness of raw materials.

- We have repaired a huge number of asphalt batching plants of different manufacturers and were able to make our own-made asphalt concrete plants very reliable and economical.

- Our pride is the price. Low rouble exchange rate allows our units to easily compete even with Chinese production models.

Main units of DS-185-80 asphalt plants in detail:

- Weighing system for stone aggregates VDKM-1000 (tensometric)

- high hardness and increased capacity design;

- shutter in bearing units that reduces friction and ensures easy opening;

- opening the shutter with one standard pneumatic cylinder;

- weighing of materials by beam type tension sensors;

- Sieve

- high hardness and increased capacity design;

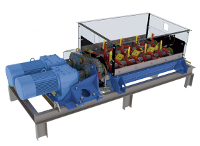

- Mixer UDM-60М.1000

- Mixer capacity - 0,77 m3;

- Nominal capacity of premix - 900 kg;

- Maximum capacity of premix - 1000 kg;

- Gear-2 cylindrical 2-step motor reducers;

- Electric motor power – 22 kW×2=44 kW;

- Torsion torque- 3000 N*m×2=6000 N* m;

- Resource - guaranteed life of electric motor - 1 year, of reducer - 3 years, resource of motor reducer - 15000 hours. Service factor - medium and hard conditions of work.

Main Technical Characteristics of All Units Supplied by Standard Railway Containers:

| Name of index | Value (nominal) |

| General data | |

| Technical output | not less than 72 t/h |

| Mobility | Modulus quickly collapsible construction in standard railway container dimension |

| Dust utilization method | Reusing in technical process or utilization |

| Bitumen heating method | Heater (coolant-oil) Flame tube |

| Mixer and weighing systems type | Weighing (automation) for stone aggregates, bitumen, mineral powder and batch additives |

| Mixer components arranging | Mixing tower |

| Number of feed bins | 4 |

| Total capacity of feed bins | not less than 38 m 3 |

| Feed weighing systems type | volumetric belt |

| Number of mineral aggregate fractions to be dosed | 4 |

| Hot aggregate bins capacity | not less than 9 m3 |

| Mixture mass | not less/not more than 900/1000 kg |

| Mineral powder supply bins capacity | not less than 26 m 3 |

| Bitumen tanks capacity | not less than 35 m3 |

| Dust collecting type | combined - dry (cyclones), wet |

| Fuel type | bunker oil – mazut 100 ГОСТ10585-75; diesel oil Л-02 ГОСТ 305-82 |

| Operation type | automatic, manual, remote |

| Maximum t of the bitumen | 453 (180) К (°С) |

| Working devices gear | electric & pneumatic |

| Nominal pressure in pneumatic system | 0,7 MPa |

| Plant accounting | accounts summing & storage |

| Installation power Electric motors power Electric heater power |

250 kW 235 kW 15 kW |

| **Fuel consumption (fuel oil 100 ГОСТ 10585-75) | not more than 600-700kg/h |

| **Specific consumption of equivalent fuel | not more than11-12 kg/h |

| **Specific energy consumption (per tonne of mix) | 4,92-7 kW•h /t |

| Climatic conditions of exploitation: Value of climatic factors according to ГОСТ 15150-69 |

normal |

| **Indices are calculated according to main technical output parameter when making asphalt concrete mixtures according to ГОСТ 9128- 84 from initial aggregates with primary moisture 5% and Δt=140°C | |

| Climate | moderate, tropical |

| Environment t° not lower not higher |

273 (0) К (°С) 313 (+40) К (°С) |

| Weight constructive | Not more than 82 t |

| Dimensions (L×W×H) | Not more than 31×36×19 m |

| Feed Unit | |

| Number of bins | 4 |

| One bin capacity | 9,5 m3 |

| Bin loading height | 3,2 m |

| Bin loading width | 3,1 m |

| Feeder type | volumetric belt |

| Number | 4 |

| Capacity: Minimum Maximum |

0 t/h 80 t/h |

| Driving power | 1,5 kW |

| Horizontal conveyor type | belt troughed |

| Tension drum diameter | not less than 220 mm |

| Driving drum diameter | not less than 220 mm |

| Installed power of conveyor drum | 4 kW |

| Belt Conveyor (Inclined) | |

| Type | belt troughed |

| Distance between axis of drums | 7-14 m |

| Driving drum diameter | 220 mm |

| Tension drum diameter | 220 mm |

| Angle of inclination | 17º6' |

| Installed power of engine | not more than 4 kW |

| Speed of belt | 1,6 m/s |

| Drum Dryer | |

| Type | Drum, continuous, countercurrent drying system |

| Installed capacity of electric motors | 65 kW |

| Dimensions

Diameter Width Length Angle of inclination |

1.5 m 1.5 m 6 m 3-3.50 |

| Rotation frequency | 10.5 с-1(r/m) |

| Burner operating | remote |

| Main fuel type | wet ГОСТ 10585-75 |

| Fuel tank capacity | 7 t |

| Smoke chimney height | 12 m |

| Smoke chimney diameter | 0,8 m |

| Technical Specifications of Gas Treatment Equipment** | |

| Dust Collection shared efficiency (all systems) | 99,2% |

| **Modifiable parameters of technical specifications depend on specific conditions of asphalt plant operation including on the amount of dust and clay particles in raw materials | |

| First stage of filtration Type |

In-line axial cyclone diameter-300 |

| Resistance | 40 mm |

| Dust collection efficiency | 40% |

| Second stage of filtration Type |

group of cyclones |

| Number of cyclones | 4 |

| Resistance | 76 mm |

| Dust collection efficiency | 96% |

| Third stage of filtration Type |

Wet fas clening of the shok-inertial action |

| Water consumption | not more than 0,15 m3/h |

| Amount of removed dust | 22 kg/h |

| Resistance | 145 mm |

| Dust collection efficiency | 70% |

| Amount of dust emitted into atmosphere through the chimney | 8,2 kg/h |

| Exhaust fan of dust cleaning system Type |

ДН-11,2 fifth execution model |

| Flap opening actuator drive gear | MEO-40/63-0,25-82I, DKJ-4100W |

| Electric motor power | 45 kW |

| Full pressure when t of flue gases 100-120°С | 270 mm |

| t of flue gases at the outlet of dryer drum | 440 (167) К (°С) |

| t of masonry materials at the outlet of dryer drum | 433 (160) К (°С) |

| Hydraulic resistance of dust collector | 250 mm |

| Water pressure of reverse water supply | not more than 0,6 (6) kPa (kgf/cm2) |

| Dust collection of flue gases at the outlet of dryer drum at the outlet of in-line axial cyclone at the outlet of cyclone unit emitted into the atmosphere |

115,4 g/nm3 75 g/nm3 3 g/nm3 1,8 g/nm3 |

| Mixing unit | |

| Type | tower with periodic actor mixer |

| Installed power electric motor | not more than 65 kW |

| Elevator type | chain, vertical with closed buckets, gravity discharge |

| Productivity | 72 t/h |

| Lifting height of material | 16 m |

| Bucket capacity | 5 l |

| Speed of chain | 0,7 m/s |

| Mixer type | 2 cylindrical 2-stage motor-gearboxes, torque on the same shaft: 240 H*m. Motor power: 22 kW*2. Folding type shutter. |

| Mass of one batch | 900-1000 kg |

| Cooling time of the batch | not more than 60 s |

| Sieve type | inertial |

| Number of sorted fractions | 4 |

| Fraction sizes | up to 0-5; 5-12; 12-20; 20-40 mm |

| Static moment | not less than 1,5 kg•m |

| Screening area | not less than 6,7 m2 |

| Nominal motor power | not less than 5,5 kW |

| Dissemination angel | 120 |

| Oscillation frequency of fractionation unit | not less than 16,5 Hz |

| Operating weight of fractionation unit | not less than 2100 kg |

| Hot aggregate bins capacity | not less than 9 m3 |

| Weighting batcher | |

| Maximum load | 1000 kg |

| Minimum load | 50 kg |

| Calculation of fractions | Strain cumulative |

| Installation of fractions doses | remote, stepless |

| Error weight of doses | ±3% |

| Bitumen weighting system | volumetric heated, with strain gauge weighting |

| Limit of dosing | 70 l |

| System pressure of the input bitumen into mixer | 0,29 (2,9) МPа (kgf/cm2) |

| Batching eror | ±1,5% |

| Amount of travel by the mixing unit (HxW) | 3,5х3,6 m |

| Mineral powder unit | |

| Capacity of mineral powder unit bin | not less than 26 m3 |

| Bag filter with shaking system | |

| Installed motor power | not more than 11 kW |

| Heater for bitumen | |

| Type | periodic action with flame tubes (AMG tibes) and heat excahgers |

| t of bitumen delivered into mixer | up to 453 (180) К (°С) |

| Tank capacity | 35 t |

| *Used fuel: | buncer oil ГОСТ 10585-75 |

| Fuel consumption of bitumen heating nozzle | up to 35 kg/h |

| Installed power | 6,5 kW |

| Pump station of coolant | |

| Coolant | oil industrial АМТ-300, И-20А, И-30А ГОСТ 20799-75 |

| Amount of oil poured in the system | 750-800 l |

| Performance of pump then pumping coolant with viscosity of 0,75 sm2/с | not less than 1,0 (3,6) l/s (m3/ч) |

| Installed power of electric motor | 2,2-7,5 kW |

| Fuel tank | |

| Tank capacity | not less than 7 m3 |

| Preheating t of fuel (мазут 100) in the tank before the nozzle |

not less than 353 (80) К (°С) not less than 393 (120) К (°С) |

| Pump performance at the speed 1400 rpm | 0,4 (1,4) l/s (m3/h) |

| Installed power | not more than 4,5 kW |

| Bitumen pipelines (from heater for bitumen to mixer) | |

| Nominal bore (internal diameter) | 80 mm |

| Number of pump stations | 1 |

| Pump type | gear |

| Capacity | 20 t/h |

| Pneumatic system | |

| Compressor type | Piston, 2-speed |

| Capacity | 0, 8 m3/min |

| Pressure | 0,6(6)-0,8(8) МPа (kgf/cm2) |

| Installed power | 7,5 kW |

| Construction. Staff training. 1000 tonns of asphalt output | 20000 $ |